Quick Link

Quick Contact

Address

Yangshan Industrial Park Huishan District Wuxi Jiangsu China

Tel

86-510-83958900

Our Newsletter

Subscribe to our newsletter for discounts and more.

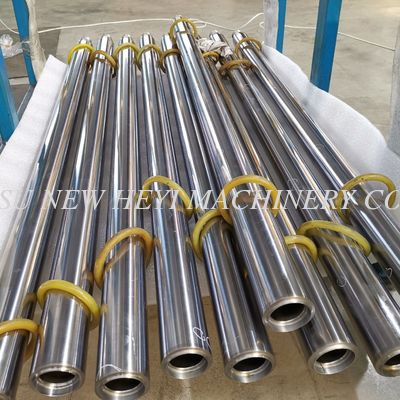

Hardened Surface 20MnV6 Chrome Piston Rod Custom Diameter The piston-rod material 20MnV6 hard chrome plated with the material number 1.5217 is suitable for universal use and is very tough and corrosion-resistant. Hard chrome plating means that an especially thick chrome layer is applied between pre-honing and finishing the honing process. The layer thickness depends on the rod diameter and has a hardness of more than 800 HV. Hard chrome plated piston rods can be used between

Hardened Surface 20MnV6 Chrome Piston Rod Custom Diameter

The piston-rod material 20MnV6 hard chrome plated with the material number 1.5217 is suitable for universal use and is very tough and corrosion-resistant. Hard chrome plating means that an especially thick chrome layer is applied between pre-honing and finishing the honing process. The layer thickness depends on the rod diameter and has a hardness of more than 800 HV. Hard chrome plated piston rods can be used between -15°C and 200°C.

| Item | Hard Chromed Bar | Induction Hardened Chromed Bar | Nickel and Chrome Plating Bars |

| Steel Grade | C45E (EN 10083) | C45E (EN 10083) | C45E,20MnV6/38MnVS6 |

| Tolerance | ISOf7 | ISOf7 | ISOf7 |

| Roundness | Diameter tolerance / 2 | diameter tolerance / 2 | diameter tolerance / 2 |

| Standard Length |

-for Ø ≤ 60 mm: 5600 -6200mm -for Ø≥60 mm: 5800 -7200mm Upon request: special lengths on all diameters |

- for Ø ≤ 60 mm: 5600 – 6200 mm - for Ø ≥ 60 mm: 5800 – 7200mm Upon request: special lengths on all diameters |

Up to 6000 mm

Upon request: special lengths on all diameters |

| Surface Roughness |

Ra max. 0.20 µm (statistic average: 0.05-0.15 µm) |

Ra max. 0.20 µm (statistic average: 0.05- 0.15 µm) |

Ra max. 0.20 µm (statistic average: 0.05-0.15 µm) |

Chrome Piston Rod Detailed Description

1. CHEMICAL COMPOSITION(%)

|

Material |

C% |

Mn% |

Si% |

S% |

P% |

V% |

Ni |

Cr% |

Mo |

Cu |

|

ck45 |

0.42-0.50 |

0.50-0.80 |

0.17-0.37 |

≤0.035 |

≤0.035 |

|

≤0.25 |

≤0.25 |

|

≤0.25 |

|

ST52 |

≤0.22 |

≤1.6 |

≤0.55 |

≤0.04 |

≤0.04 |

0.02-0.15 |

|

|

|

|

|

20MnV6 |

0.17-0.24 |

1.30-1.70 |

0.10-0.50 |

≤0.035 |

0.035 |

0.10-0.20 |

≤0.30 |

≤0.30 |

|

≤0.30 |

|

42CrMo |

0.38-0.45 |

0.5-0.8 |

0.17-0.37 |

≤0.035 |

≤0.035 |

0.07-0.12 |

≤0.03 |

0.90-1.20 |

0.15-0.25 |

≤0.03 |

|

40Cr |

0.37-0.45 |

0.50-0.80 |

0.17-0.37 |

≤0.035 |

≤0.035 |

|

≤0.3 |

0.80-1.1 |

|

≤0.03 |

|

HY4700 |

0.38-0.45 |

1.20 ~1.60 |

0.30~0.50 |

≤0.035 |

≤0.020 |

0.05~0.15 |

≤0.25 |

0.10~0.20 |

≤0.15 |

0.25 |

|

HY4520 |

0.40 ~0.48 |

0.80 ~1.40 |

0.15 ~0.35 |

≤0.035 |

≤0.035 |

≤0.15 |

≤0.25 |

≤0.25 |

≤0.15 |

≤0.25 |

Chrome Piston Rod MECHANICAL PROPERTIES

|

Material |

T.S / Rm(MPa) |

Y.S / Rel(MPa) |

A% |

CHARPY |

CONDITION |

|

ck45 |

610 |

355 |

16 |

>41J |

Normalized |

|

ck45 |

800 |

540 |

20 |

>41J |

Q+T |

|

ST52 |

500 |

355 |

22 |

|

Normalized |

|

20MnV6 |

750 |

590 |

12 |

>40J |

Normalized |

|

42CrMo4 |

980 |

850 |

14 |

>47J |

Q+T |

|

40Cr |

1000 |

800 |

10 |

|

Q+T |

Chrome Piston Rod MICRO ALLOY STEEL

|

Material |

MECHANICAL PROPERTIES |

Surface hardness(HBW) |

|||||

|

Rm(MPa) |

Rel(MPa) |

A% |

Z% |

KU2(J) |

|

||

|

HY4700 |

Φ35 - Φ100 |

900 - 1100 |

≥650 |

≥16 |

≥35 |

≥39 |

270-340 |

|

>Φ100 - Φ140 |

850 - 950 |

≥600 |

≥16 |

≥35 |

≥39 |

270-340 |

|

|

HY4520 |

Φ40 - Φ100 |

750 - 900 |

≥520 |

≥19 |

≥40 |

≥39 |

230-290 |

|

>Φ100~Φ140 |

750 - 900 |

≥520 |

≥17 |

≥35 |

≥39 |

230-290 |

|

|

|

|

|

|

|

|

|

|

Meeting clients' requirements is our forever goal.

Benefit mutually and go forward hand in hand.